Product Category

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

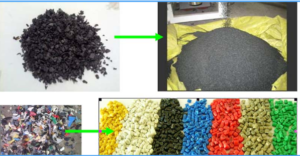

- Waste plastic recycle and granulator machine

- Auxiliary machine

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

- Waste plastic recycle and granulator machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu’an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

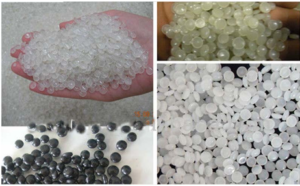

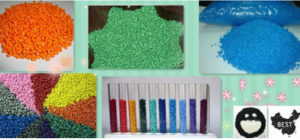

PP PE PC ABS PET PS granulator machine

PP PE HDPE LDPE LLDPE Plastic pelletizer pelletizing granules making granulator machine

1. Applications:

Applicable plastic materials: PP, HDPE, LDPE, LLDPE etc.

Material resource: PE bag, printed LDPE film, film (rolls, loose, bundles), agricultural film waste, polypropylene (non-woven), woven bag

2. The advantage of plastic granulator :

1. Greatly increase output

2. Continuous production

3. Flexible granulating style

4. Finished product particle plasticizing better, no pores

5. Main parts (reducer, motor, inverter) use domestic well-known brand, quality have assurance, equipment with long life and good performance.

According to different raw material , the granulators are devided to the following type:

such as : PP PET PP PS ABS EVA(no foaming) TPU(but parallel twin screw much better) PA , there is a pre-condition is : single

screw extruder only use to common recycle waste plastic to be granules, if want to make function master batch with adding

additives, twin screw extruder is the best.

2. Conical screw extruder suitable to make PVC granules only. because its short screw and barrel, can avoid PVC burning , because

PVC material’s special characters.

3. parallel twin screw extruder suitable to make

++filling modification : PE PP EVA ABS PC PS +Caco3, Talc powder , barium sulfate, aluminum hydroxide magnesium hydroxide SiO2,

etc.

++ blending modification (rubber and plastic compounding , plastic alloy)

Such as : PP PE PS +SBS PP PA+EPDM POE PP+NBR EVA+SILICON ABS+TPU PC+ABS etc.

++ color master batch : PE PP EVA PS PBT PET + color and other additives

++functional granules such as Degradable granules : PE PS PP+starch , anti firing granules : PP PE PA ABS PBT+ fire retardant.

Carbon black , fiber , and other special use granules . like PBT AS PA PC POM PPS PEEK PPO PES +FIBER .

++thermoplastic elastic material like TPR TPU TPV SEBS SIS .

++ varies cable material like HDPE LDPE LLD PE MDPE PP EVA insulation materials , crosslink material .

++ other reactive , devolatilization and powder coating material

4. Double stage extruder suitable to make foamed material recycle like foam PE sheet , foam PS sheet. Also can use to recycle

film to be granules .

With side compressor extruder special use to recycle film . because film is light and thinner , not easy to feeding to extruder

feeding hole, compressor can force the film into the screw directly . this function similar as side feeding system with screw .

1、water cooling strand cutting system

Machine consist of extruder , screen changer, mould , water cooling tank , air blower and cutter unit.

This cutting system suitable mostly material’s cutting

2 、air blow cooling hot cutting system

Consist of feeding system , extruder, air cooling hot face cutter, cyclone , and vibrating sieve.

Applications : enforcing modification material such as PE , EVA etc +caco3, talc, TIO2, PP PVC , CARBON BLACK , degradable master

batch like PE PP +starch , additives . and anti flame master batch such as PE EVA+SB2O3, MgOH2, AL2OH3 etc.

3、water ring cooling cutting system

Consist of feeding system , extruder, water-ring granulator , centrifugal dewatering , vibration sieve container . This cutting

system cut tablet shape pellets , material can be PE EVA etc filled with CACO3, talc TIO2, carbon black ,etc, cable sheath , cable

insulation, compounds of LDPE , HDPE LLDPE or MDPE. Radiation cross link material, heat-shrinkable material, cable compounds, hot

melt adhesives , color master batch and other degradation material.

4、underwater cutting system

The pelletizing currently is the special and innovative technique for the production of high-quality plastics pellets, is used to

produce marketable pellets having very low viscosity and high elasticity , or having special shape requirements such as

micro-particle shape, ball shape , this is very difficult to perform by strand cooling cutting and water ring cooling cutting

system.

Example : TPU EVA PA PP TPE TPV TPR TPEE PA series , PC PET PBT PE POM EPDM, etc.

This system very important for different material , some material must use the special feeding system.

Example : waste film recycle need special designed force feeding system to press the film into the extruder.

Additives such as caco3, such as talc , need special designed powder feeding system .

Also feeding place is different , some material must feed to the screw directly , some material need feed to the hopper first .